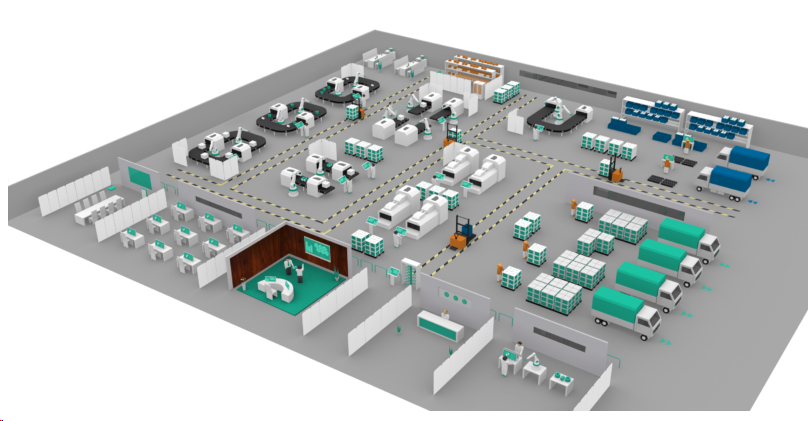

In the fourth industrial revolution, the fusion of technology and manufacturing has given rise to the smart factory—a symbol of Industry 4.0. At the heart of this revolution lies the Bluetooth beacon, a small yet powerful device that is redefining the way factories operate. This article delves into the role of Bluetooth beacons in the smart factory, exploring their capabilities, applications, and the transformative impact they have on industrial automation.

The Beacon’s Role in the Smart Factory

Bluetooth beacons are low-energy broadcasting devices that emit signals to nearby Bluetooth-enabled devices. In a smart factory, beacons serve as the nervous system, providing real-time location-based services and data collection that drive efficiency and innovation.

Enhancing Efficiency with Beacons

- Asset Tracking: Beacons can be attached to equipment, tools, or inventory, allowing for real-time tracking and management. This helps in locating assets quickly, reducing downtime, and improving operational efficiency.

- Maintenance Alerts: By integrating with sensors, beacons can monitor the health of machinery and send alerts for maintenance, preventing unexpected breakdowns and extending the lifespan of equipment.

- Workflow Optimization: Beacons can guide workers to the correct workstations, ensuring that tasks are completed in the most efficient order, reducing idle time, and enhancing productivity.

- Safety and Security: Beacons can be used for proximity alerts, ensuring that workers are aware of potential hazards or restricted areas, thus improving workplace safety.

Applications of Bluetooth Beacons in Industry

- Warehouse Management: Beacons can streamline the process of inventory management by providing real-time updates on stock levels and locations, enabling just-in-time inventory systems.

- Quality Control: By tracking the movement of products through the production line, beacons can help in monitoring quality control checkpoints and ensuring that only合格的产品 proceed to the next stage of production.

- Tool Management: Beacons can keep track of tools used in the assembly line, ensuring that the right tools are available when needed and reducing the time spent searching for them.

- Energy Efficiency: Beacons can help in monitoring energy usage patterns, identifying areas of waste, and implementing energy-saving measures.

Challenges and Considerations

Despite their potential, there are challenges to implementing Bluetooth beacons in a factory setting:

- Infrastructure Integration: Integrating beacons with existing factory infrastructure can be complex and may require significant investment in hardware and software.

- Data Security: As with any IoT device, ensuring the security of the data transmitted by beacons is crucial to protect against cyber threats.

- Interference: In industrial environments with heavy machinery and other wireless devices, there is a risk of signal interference that can affect the reliability of beacons.

The Future of Bluetooth Beacons in Industry

As technology advances, the capabilities of Bluetooth beacons are expected to expand. Future beacons will likely offer improved data processing capabilities, enhanced security features, and more sophisticated analytics, further solidifying their role in the smart factory.

Conclusion

Bluetooth beacons are the unsung heroes of the smart factory, working tirelessly behind the scenes to enhance efficiency, improve safety, and drive innovation. As we continue to embrace the fourth industrial revolution, the role of beacons in the factory floor is set to become even more pivotal, ensuring that the smart factory remains at the cutting edge of manufacturing excellence.